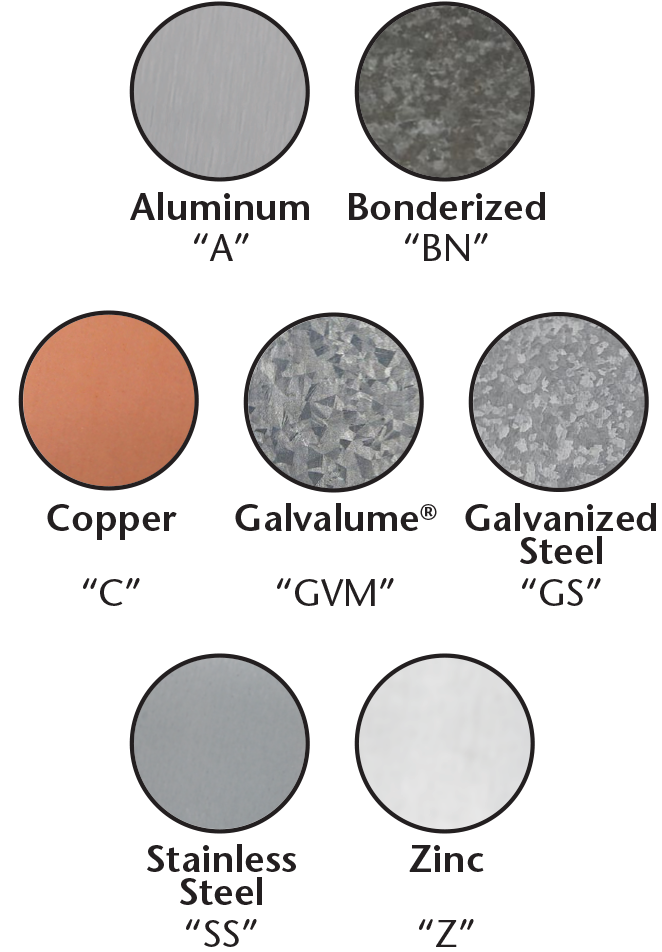

Metal Materials And Finishes Guide

Most of our products can be manufactured in Aluminum, Bonderized, Copper, Galvalume®, Galvanized Steel, Stainless Steel or Zinc. Custom shapes and radius shapes are available. Clear anodized finish and paint are not available on any metal items.

Please note, not all metal items are available in stock in all the available metals, size and finish combinations listed. Please call 1-87-Stockton to verify availability.

Available Materials

10ga. Galvanized Steel* | GS 10ga |

12ga. Galvanized Steel* | GS 12ga |

14ga. Galvanized Steel* | GS 14ga |

16ga. Aluminum .050 | A 16ga |

16ga. Galvanized Steel* | GS 14ga |

18ga. Aluminum .040 | A 18ga |

18ga. Galvanized Steel* | GS 18ga |

20ga. Aluminum .032 | A 20ga |

20ga. Galvanized Steel* | GS 20ga |

22ga. Aluminum .025 | A 22ga |

22ga. Galvanized Steel* | GS 22ga |

26ga. Bonderized | BN 26ga |

26ga. Copper or 16 oz (.0216) | C 26ga |

26ga. Galvalume® | GVM 26ga |

26ga. Galvanized Steel* | GS 26ga |

26ga. PaintLoc | PTL 26ga |

26ga. Stainless Steel 304#2B | SS/2 26ga |

26ga. Stainless Steel 304#4 | SS/4 26ga |

26ga. Zinc | Z 26ga |

3/16 Hot Roll Steel | HR 3/16 |

1/4 Hot Roll Steel | HR 1/4 |

*Galvanized Steel G-90, unless otherwise specified.

Available Finishes

Galvanized: "GS"

Galvanized steel is produced by submerging cold rolled steel in a molten bath of zinc. This is referred to as a "hot dip" process. Once the material is removed from the zinc bath it reacts to oxygen in the air which solidifies the bond between the zinc and the steel, leaving a "spangled" finish visible on the material. The zinc coating offers a protective layer to prevent rust and corrosion, making it ideal for HVAC, construction and other manufacturing applications.

Bonderized: "BN"

Bonderized steel is actually Galvanized G90 that has been put through a phosphate bath and has a layer of Chromate applied and dried leaving it ready to accept paint. The process produces a dull gray colored finish. Bonderized is commonly referred to as "Paint Grip".

Galvannealed (Jet Kote): "JTC"

Galvannealed Steel is carbon steel coated with zinc via a hot-dip process similar to Galvanizing. Once the steel is removed from the molten zinc it is Immediately subjected to a heat treatment. This causes a reaction which results in a unique zinc-iron alloy coating on the surface of the steel.

The galvannealed surface has a non-spangled matte finish, which is very different than the highly metallic appearance of a standard galvanized coating. At times, the galvannealed coating may appear similar to uncoated cold rolled steel. One of the primary attributes of galvannealed steel is that the surface accepts paint very readily, even without pretreatment.

Stainless Steel Finishes

Click below to review a list of the common stainless steel finishes we offer. Special finishes upon request.

Stainless Steel Finishes

Electro Galvanized (Paint Loc): "PTL"

Electro Galvanized Steel is a zinc coated carbon steel similar to Galvanized and Galvannealed. The process consists of immersing the steel in a cold zinc "bath" that has an electrical current running through it. The result is a uniform layer of zinc bonded to the steel electrolytically to prevent corrosion. Key points include a uniform distribution of extremely thin zinc coating leaving a spangle free finish that welds easily and has good paintability.

Hot Rolled: "HR"

Hot Rolled Steel is the most rudimentary form of carbon steel and is found in a wide range of industries. The process involves rolling steel at high temperatures which prevents recrystallization so the steel can be easily flattened and formed. It is also typically cheaper to manufacture than other forms of carbon steel because the progression usually doesn’t require a cooldown and reheating process.

Hot rolled products will have a scaly grey finish that is generally a bit rougher than other types of steel that we offer. A natural orange rust will appear on the surface of hot rolled material if it remains exposed over time. This surface finish is desired/accepted by most hot rolled users.

Cold Rolled: "CR"

Cold Rolled Steel is created by rolling Hot Rolled P&O at room temperature, below its recrystallization point, to create thinner gauges and a harder surface. It then undergoes an annealing process to regain some of its ductility. In addition to improvement of mechanical properties, cold rolling results in more control over the dimensions and appearance of the finished product. You are left with a smoother, more predictable and aesthetically appealing surface.